Precise drive solutions for the photovoltaic industry

The photovoltaic industry requires a high degree of precision: All steps in solar wafer and cell production, in laminating solar modules, and in the various handling processes must be carried out with high precision. Any deviation comes at the expense of quality and leads to complex post-processing or even to scrap, with a negative effect on the yield.

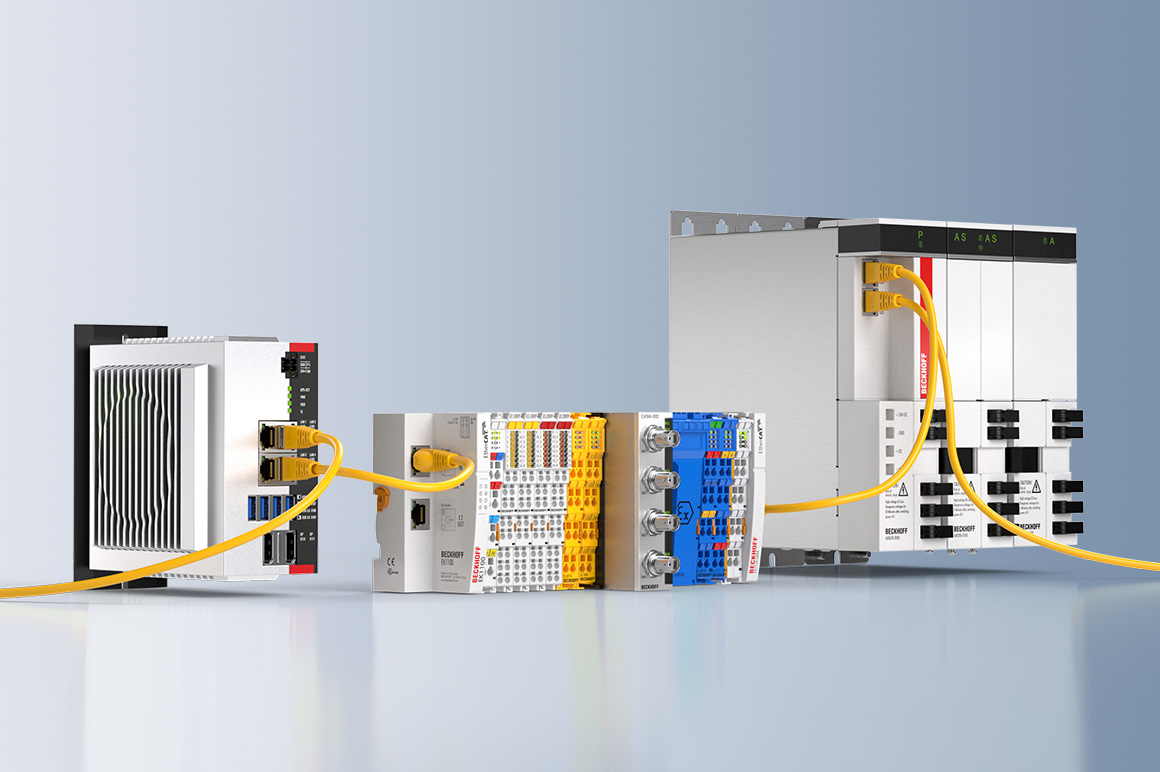

With our unparalleled range of technologies in the world of electric drives, we offer our customers a clear technological edge over the competition, whether it’s multi-axis servo systems with synchronous servomotors, highly dynamic linear servomotors, compact electric cylinders, tubular motors, or compact drives for the low-voltage range – we provide high-precision drive technology for every application.

Advantages of scalable drive technology at a glance:

- many drive technologies, one system: combine and precisely synchronize a wide variety of drive and handling technologies to suit your needs

- One Cable Technology: combines the power and feedback system in a single standard motor cable, saving installation space and time

- safety included: TwinSAFE safe automation technology is available for all Beckhoff drive solutions